你就

你就计划

不恐怖/不Vibrating Screen

VIBEPRO

From Machinery Sources to Global Supply

你就

你就From Machinery Sources to Global Supply

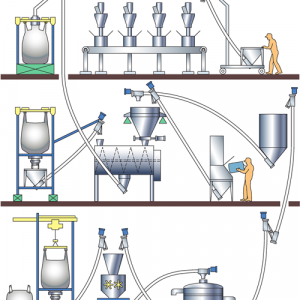

Vibepro Conveyor Buying Guide: Choose the Right Conveyor System for Your Needs Introduction: Welcome to Vibepro’s Conveyor Buying Guide, your comprehensive resource for selecting the

Description: The VP-MCS Mining Circular Vibrating Screen is specifically engineered for efficient screening of various materials in the mining industry. Constructed from durable carbon steel or stainless steel materials, it ensures longevity and reliability even in demanding environments. The screen diameter can be adjusted to accommodate different throughput requirements, typically ranging from 1000mm to 3000mm. With adjustable screen layers, ranging from 1 to 3 layers, it offers versatility in screening different particle sizes. The vibration frequency is adjustable, typically ranging from 800 rpm to 1200 rpm, providing optimal screening efficiency. Featuring a sturdy frame and high-quality vibration motor, it delivers stable and consistent performance. With customizable settings and a user-friendly interface, operators can easily adjust the amplitude and frequency settings to suit specific screening needs. The VP-MCS Mining Circular Vibrating Screen is the ideal solution for efficient and reliable screening operations in the mining industry, ensuring high productivity and quality output.

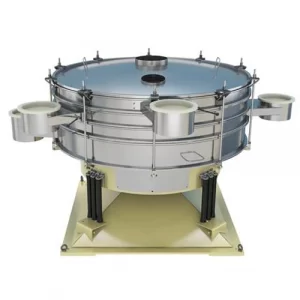

Description: The VP-RUS Rotary Ultrasonic Vibrating Screen integrates rotary and ultrasonic vibration technologies for enhanced screening efficiency. Constructed from high-quality stainless steel or carbon steel materials, it ensures durability and reliability in various screening applications. The variable screen diameter, typically ranging from 400mm to 2000mm, provides flexibility to accommodate different throughput requirements. With adjustable screen layers, ranging from 1 to 4 layers, it offers versatility in screening various particle sizes. The combination of rotary and ultrasonic vibration enables efficient and precise screening, ensuring high-quality separation of materials. Operators can adjust the ultrasonic frequency, typically ranging from 25 kHz to 40 kHz, to optimize screening performance. The VP-RUS Rotary Ultrasonic Vibrating Screen is the ideal choice for applications requiring superior screening efficiency and precise particle separation.